Tungsten Copper Used for EDM and ECM

Description

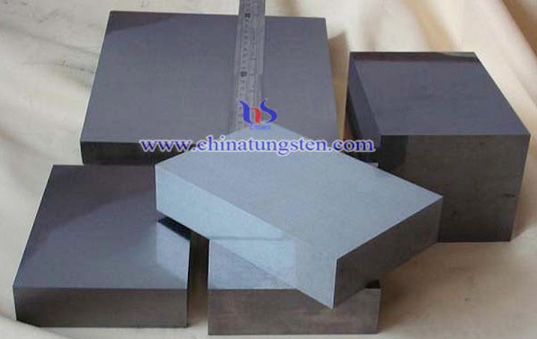

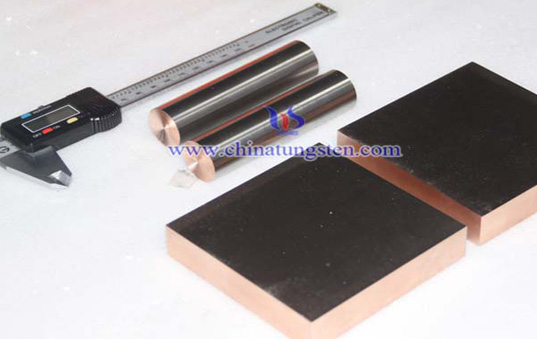

Due to excellent properties in arc erosion, fusion resistance, tungsten copper block is widely used as electrode materials in EDM and ECM.

Features

Tungsten copper has good wear resistance, high MRR (Material Removal Rate) and precision, especially for tungsten carbide (WC) and other materials with high hardness machining.

Applications

Tungsten copper is widely used in EDM and ECM. EDM is a kind of process that ablate the metal by rapidly repetitional discharge. ECM including electrolytic machining, electric grinding, electrochemical polishing, electroplating and electroetching, etc.

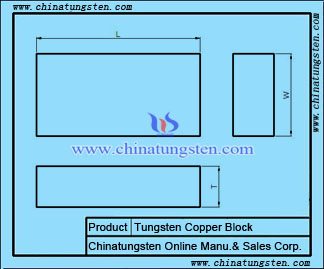

Specifications (mm)

| D1×100×100 | D2×100×100 | D3×100×100 | D4×100×100 | D5×100×100 | |||

| D6×100×100 | D7×100×100 | D8×100×100 | D9×100×100 | D10×100×100 | |||

| D12×100×100 | D15×100×100 | D16×100×100 | D18×100×100 | D20×100×100 | |||

| D22×100×100 | D25×100×100 | D30×100×100 | D35×100×100 | D40×100×100 | |||

| D45×100×100 | D5×100×200 | D6×100×200 | D8×100×200 | D10×100×200 | |||

| D12×100×200 | D15×100×200 | D20×100×200 | D25×100×200 | D30×100×200 | |||

| The standard length and width of tungsten copper block we are able to provide is less than 300mm, and the thickness is more than 0.1mm (±0.05mm), customized sizes and tolerances are also accepted. | |||||||

More information about other grades or properties, please visit: Traditional Grade